Sanitary Napkin Production Line

Sanitary Napkin Production Line

Full-Servo Sanitary Napkin Machine

Full-Servo Sanitary Napkin Machine

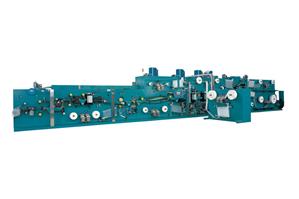

Semi-Servo Sanitary Napkin Machine

Semi-Servo Sanitary Napkin Machine

Inverter Controlled Sanitary Napkin Machine

Inverter Controlled Sanitary Napkin Machine

Pulp Core Sanitary Napkin Machine

Pulp Core Sanitary Napkin Machine

Ultra-Thin Sanitary Napkin Machine

Ultra-Thin Sanitary Napkin Machine

Easy-Open Packing Sanitary Napkin Machine

Easy-Open Packing Sanitary Napkin Machine

Panty Liner Production Line

Panty Liner Production Line

Machine Direction Panty Liner Machine

Machine Direction Panty Liner Machine

Cross Direction Panty Liner Machine

Cross Direction Panty Liner Machine

|

Name |

Quantity

|

Brand |

Country Of Origin |

|

Servo Motor |

41

|

Siemens or Mitsubishi |

Germany or Japan |

|

Web Guide |

5

|

Techmach or BST

|

USA or Germany |

|

Touch Screen |

1

|

Siemens or Mitsubishi |

Germany or Japan |

|

PLC Control System |

1

|

Siemens or Mitsubishi |

Germany or Japan |

|

Sensor |

43

|

Sick, Omron, DELIXI |

European/Japanese |

|

Safety Protection-Phase Switch, stay wire Switch |

60

|

Schmersal |

Germany |

|

Hot Melt Applicator |

5

|

ITW or Nordson |

USA |

|

Material of Cutter D2 |

3

|

A.finkl |

USA |

|

Bearing (according to use) |

1

|

BEM/NSK/SKF |

Germany/Japan/Sweden |

|

Timing Belt |

1

|

Optibelt/Gates |

Germany/USA |

|

Low-voltage Electrical Equipment |

1

|

Schneider |

France |

|

Electric connect terminal |

1500

|

Phoenix Contact |

Germany |

|

Temp. control system |

2

|

Omron |

Japan |

|

High speed rotation connection |

12

|

SMC |

Japan |

|

relief valve |

8

|

SMC |

Japan |

|

pneumatic component |

1

|

SMC |

Japan |

|

Solenoid valve |

60

|

SMC |

Japan |

|

Water content segregator |

1

|

SMC |

Japan |

|

Failure automatic warning |

1

|

Mitsubishi |

Japan |

|

Mercury conducting ring |

2

|

ASSIAN TOOL |

Taiwan China |

|

Planet speed reducer |

5

|

VGM |

Taiwan China |

|

Motor |

6

|

Siemens |

Germany |

|

Automatic rejection system |

1

|

Landytop |

Landytop-Company |

|

Dust recycle system |

1

|

Landytop |

JWC-Company |

|

Waste recycle system |

1

|

Landytop |

Landytop-Company |

|

Safety protect system |

1

|

Landytop |

Landytop-Company |

|

Raw material loading and unloading davit arm |

1

|

Landytop |

Landytop-Company |

|

Raw material outer-fixed system(optional) |

1

|

Landytop |

Landytop-Company |

|

Cotton Core wheel forming unit |

1

|

Landytop |

Landytop-Company |

|

SAP Feeding unit, quantity can adjusted |

1

|

Landytop |

Landytop-Company |

|

Cotton Core press embossing |

1

|

Landytop |

Landytop-Company |

|

Bottom tissue feeding unit |

1

|

Landytop |

Landytop-Company |

|

Cotton Core cutting |

1

|

Landytop |

Landytop-Company |

|

Bottom PE film feeding, automatic unwinding |

1

|

Landytop |

Landytop-Company |

|

Top layer, absorb cotton core, back sheet complex pressing |

1

|

Landytop |

Landytop-Company |

|

Urgent stop |

7

|

Landytop |

Landytop-Company |

|

Products length folding and pressing |

1

|

Landytop |

Landytop-Company |

|

Products final cutting |

1

|

Landytop |

Landytop-Company |

|

Products two folding |

1

|

Landytop |

Landytop-Company |

|

Products output |

1

|

Landytop |

Landytop-Company |

|

Pulp feeding unit with frequency controller |

2

|

Landytop |

Landytop-Company |

|

Main materials automatic run, auto connection unit |

6

|

Landytop |

Landytop-Company |

|

Tension control |

10

|

Landytop |

Landytop-Company |

|

Products output in a line |

1

|

Landytop |

Landytop-Company |

tag: Facial Mask Production Line | Facial Mask Manufacturing Machinery | facial cream making machine | body cream making machine

tag: Baby Nappies manufacturing machinery | Automatic infant baby diaper machine | semi servo disposable baby diaper making machinery | Semi Automatic Baby and Adult diaper machine