Introduction

Diaper pad machine is a special machine to produce diaper pads for babies. The function of diaper pads is similar to diapers. However, diaper pads are more economic than diapers. The main parts of diaper pads are fluff pulp, SAP, surface non-woven, bottom film and leg cuff units. The structure of diaper pad is very simple and the cost is much lower. Besides, the diaper pad machine is easy to be operated. Our company as China baby diaper machine producer, we can produce different sizes of diaper pads (large, middle and small) by replacing few parts.Main motor inverter control and mechanical transmission with differential gear boxes, universal shafts &timing belt. Each working unit minimizes the shortage of gearing system so as to make the transmission smoother. All relative parts have differential devices for phase adjustment during operation. The products can be three-folded and stacked in line for output.

Main Features of Diaper Pad Machine

1. The machine has a frequency motor driving with PLC control and touch screen.

2. Frequency unwinding, auto-tension control and auto splicing are available for raw materials.

3. There are auto reject for wasted diaper, auto detect and alarm for material exhausted.

4. This baby diaper machine can adjust phase during running without stop.

5. The machine has highly stable transmission system.

6. Our machine is designed reasonably in accord with practical needs.

7. The machine wallboard is processed by the large gantry milling machine.

Main Configurations of This Baby Diaper Machine

-

1. Inverter drive, PLC control with touch screen

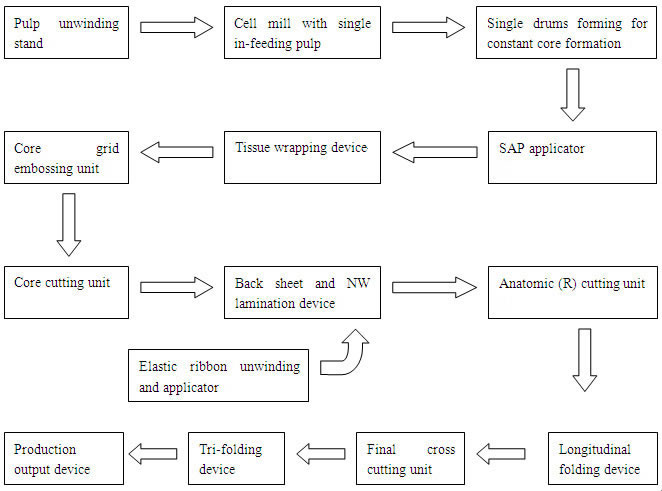

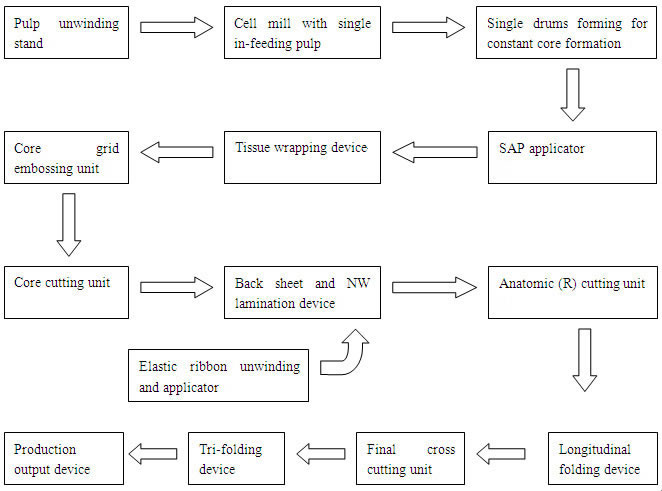

2. Pulp unwinding stand

3. Cell mill with single in-feeding pulp

4. Single drums forming for constant core formation

5. SAP applicator

6. Tissue unwinding and wrapping device

7. Core grid embossing unit

8. Core cutting unit

9. Tension control raw material unwinding unit with auto splicing

10. Elastic ribbon unwinding unit

11. Longitudinal folding device

12. Final cross cutting unit

13. Tri-folding device

14. Quality control system with reject for defective products

15. Reject gate

16. Product ordering output device

17. Bag type dust collection system

18. Safety door

Main Technical Parameters of Diaper Pad Machine

-

Production Speed: 300pcs/min

Required Power Supply: 105Kw (glue applicator and air compressor excluded)

Power: 380V, 50Hz, 3 Phases

Compressed Air: 0.6-0.8Mpa, 2.5 m³/min

Total Weight: 26 T

Dimensions: (m) L×W×H: 21×8×4.5 (for reference)

Flow Chart of Diaper Pad Production Line

Shanghai Landytop Industry Co.,Ltd. is a professional manufacturer and supplier of diaper pad machines, specializing in the production of baby diaper machines in China. In addition to these products, we also provide sanitary napkin machine, adult diaper machine, under pad machinery, maternity napkin production line, etc. Our products have gained the CE authenticate and the standard attestation of ISO9001 International Quality System with their high quality. We follow strictly the standards for machinery industry formulated by the state. Our sales cover a wide range all over the world.