Description

Semi-servo sanitary napkin machine produces sanitary napkin products used during women's menstruation. As the name indicates, semi-servo machine has two parts. One part is inverter drive, the other is servo drive. This equipment can not only save cost, but also increasing efficiency. This machine can be used in many ways. It can produce pulp core and ultra-thin sanitary napkins, easy-open packing sanitary napkin, individual packing and straight packing products. Normally, both winged and wingless sanitary napkins can be made by semi-servo sanitary napkin machine. The most typical machine is the semi-servo easy-open packing wing sanitary napkin production line. The machine can be upgraded according to customers' requirements. We use plywood pallets with plastic film for packaging and container for delivery to ensure safety.

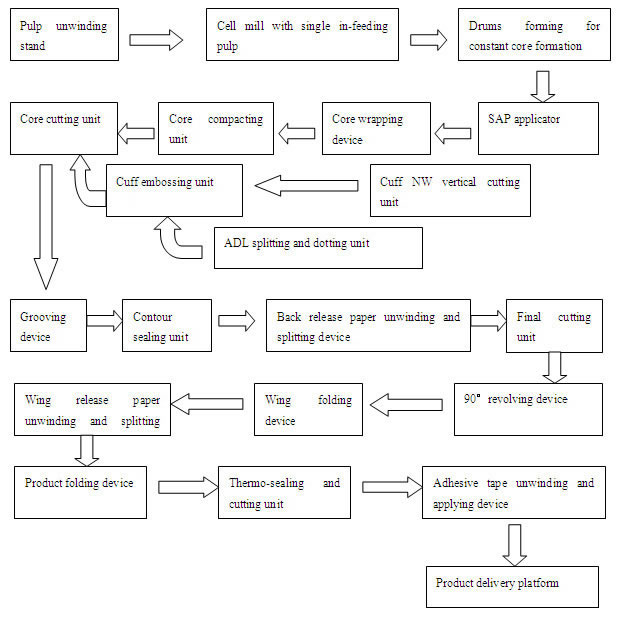

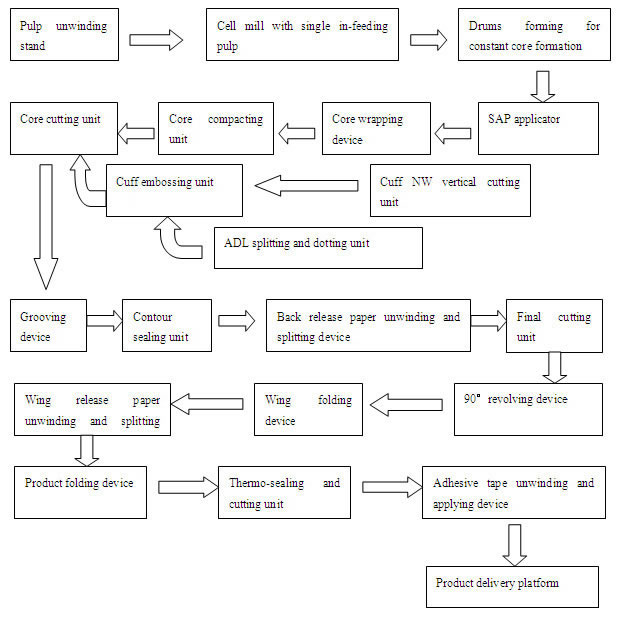

Typical line: Semi-Servo Easy-Open Packing Wing Sanitary Napkin Machine

Features of this Women Wing Sanitary Napkin Machinery

a. The drive is controlled by variable frequency.

b. Raw material servo unwinding is controlled by servo auto-controlling system.

c. There is PLC controlling equipped with touch screen.

d. Man-machine conversation interface is designed in the operating terminal to realize figure digitalized control.

e. The women wing sanitary napkin machinery has correction device and a high degree of automation.

f. The machine wallboard is processed by the large gantry milling machine.

g. Components of the machine use CNC (Computerized Numerical Control) with high processing precision.

h. The semi-servo sanitary napkin machine is designed reasonably in accordance with practical needs.

i. The machine wallboard is processed by the large gantry milling machine.

Main Configurations of this Women Wing Sanitary Napkin Machinery

-

1. Inverter drive, Raw material servo unwinding, PLC control with touch screen

2. Pulp unwinding stand

3. Cell mill with single in-feeding pulp

4. Drums forming for constant core formation

5. SAP applicator

6. Tissue unwinding and wrapping device

7. Core compacting unit

8. Core cutting unit

9. Tension control raw material unwinding unit with auto splicing

10.2 sides NW vertical cutting device

11. Side gather embossing unit

12.ADL cutting and dotting unit

13.Grooving unit

14.Contour sealing device

15.Back release paper unwinding and splitting device

16.Final cross cutting unit

17.Wing folding device

18.Wing release paper unwinding and splitting device

19.Product 90°revolving device

20. Product folding device

21.Adhesive tape unwinding and applying device

22.Thermo-sealing and cutting unit

23. Reject gate

24. Bag type dust collection system

25. Safety door

Main Technical Parameters of this Semi-Servo Sanitary Napkin Machine

-

Production Speed: 550pcs/min

Max. Production Speed: 650pcs /min

Required Power Supply: 145Kw (glue applicator and air compressor excluded)

Power: 380V, 50Hz, 3 Phases

Compressed Air: 0.6-0.8Mpa, 1.2m³/min

Total Weight: 35 T

Dimensions (L×W×H):19m×6.5m×3.5m (for reference)

Flow Chart of Semi-Servo Easy-Open Packing Wing Sanitary Napkin Production Line