Description

Baby diaper machine mainly produces baby disposable diaper products. Baby diapers are made of disposable materials. As China famous baby diaper making machine manufacturer, we have collected advantages from domestic and abroad in the similar line. The thickness can be adjusted . The pulp core will not be easily broken and shifted. Materials adhere to elastic ribbon for side leakage proof. After the arc on side is shaped, it will fold the wings and make a three-folding in lengthwise way. The diaper pads are easy for packing. The main standard electrical appliances are famous-brand products of domestic and abroad, so the lifetime of the equipment is guaranteed. Some optional functions can be chosen by customers' requirements. We use plywood pallets with plastic film for packaging and container for delivery.

Features of Baby Diaper Machine

1. The technological process is a straight production line, quick, convenient, and easy to manage.

2. The products are disposable, so it is much healthier.

3. We have safety protection unit, such as safety door and emergency stop and so on.

4. High precision, the parts are under CNC processing

5. The baby diaper machine adopts PLC control system with humanistic design.

6. The machine has high stable transmission system.

7. The diaper machine automatically stops the machine when material is broken or used out.

8. The machine wallboard is processed by the large gantry milling machine.

Main Configurations of Baby Diaper Making Machine

-

1.Inverter drive, PLC control with touch screen

2.Raw materials tension control and auto splicing

3.Quality control system with reject for defective products

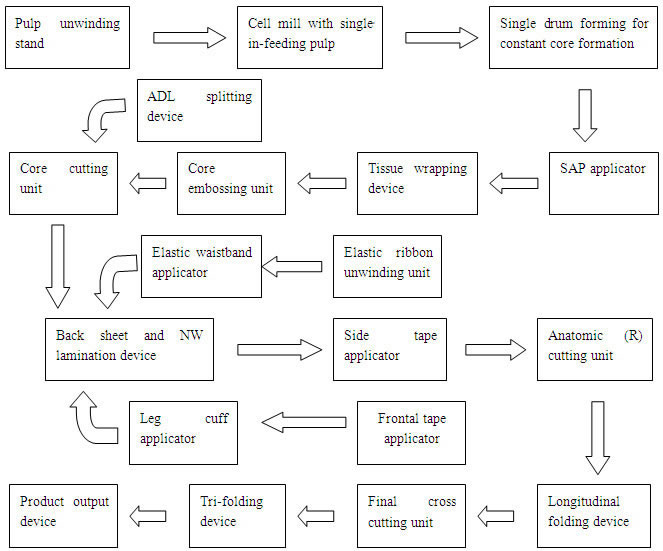

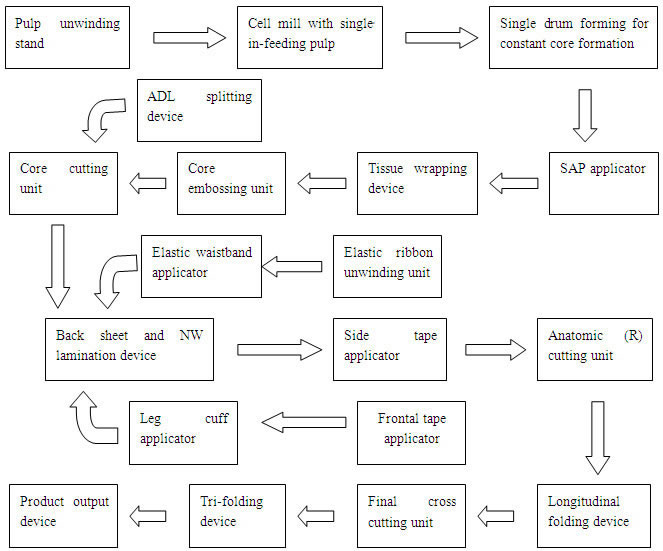

4.Pulp unwinding stand

5.Cell mill with single in-feeding pulp

6.Single drum forming for constant core formation

7.SAP applicator

8.Tissue wrapping device

9.Core embossing unit

10.Core cutting unit

11.ADL splitting device

12.Elastic ribbon unwinding unit

13.Back sheet and NW lamination device

14.Elastic waistband applicator

15.Frontal tape applicator

16.Side tape applicator

17.Leg cuff applicator

18.Anatomic (R) cutting unit

19.Longitudinal folding device

20.Final cross cutting unit

21.Tri-folding device

22.Reject gate

23.Bag type dust collection system

24.Safety door

Main Technical Parameters of Baby Diaper Machine

-

Production Speed: 350pcs/min

Max. Production Speed: 450pcs/min

Required Power Supply: 195Kw (glue applicator and air compressor excluded)

Power: 380V, 50Hz, 3 Phases

Compressed Air: 0.6-0.8Mpa, 2.5 m³/min

Total Weight: 42 T

Dimensions: (m) L×W×H: 25×7.5×3.5 (for reference)

Flow Chart of Baby Diaper Making Machine

Shanghai Landytop Industry Co.,Ltd. is a professional baby diaper making machine manufacturer in China. In addition to this product, we also provide sanitary napkin machine, adult diaper machine, under pad machinery, maternity napkin production line, hemostasia pad production line, etc. Our products have gained the CE authenticate and the standard attestation of ISO9001 International Quality System with their high quality. We follow strictly the standards for machinery industry formulated by the state. Our clients are from all over the world, including Europe, the Middle East, Africa and Southeast Asia.