Quick Details

Breast pad production line is used to produce disposable breast pads for new mothers during their lactation period. The full-servo breast pad machine can guarantee a high degree of efficiency and automation. Our company is a professional nursing pad machine producer. We adhere to study the requirements of the market, develop and apply new technology and workmanship. We also strengthen quality management to provide the most energy saving and high efficiency equipments for customers. The full-servo breast pad machine is designed reasonably conformed to the practical need. We have a high degree of automation, so it can work stably. We make use of plywood pallets with plastic film for packaging and container for delivery to ensure its safety. For payment, you can choose T/T or L/C. Our company sets a good reputation on the market and we will have a broad future owing to distinguishing features.

Features

1. It adopts servo motors and raw materials rollers automatic unwinding.

2. The machine realizes automatic splicing function in high speed circumstances.

3. This kind of nursing pad machine uses synchronous belt conveying to ensure high precision.

4.Fluff pulp is mixed with SAP. The SAP supplying amount is adjusted by servo motor.

5. The shape of fluff core embossing unit can be appointed by per client.

6. After compression, the products are vertically folded, cut and molded.

7. Final products are output in a line.

8. The machine wallboard is processed by the large gantry milling machine.

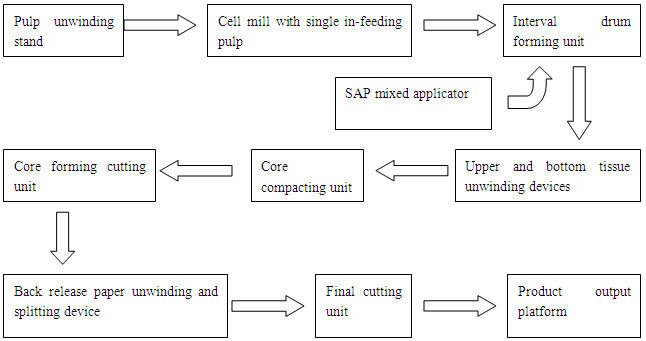

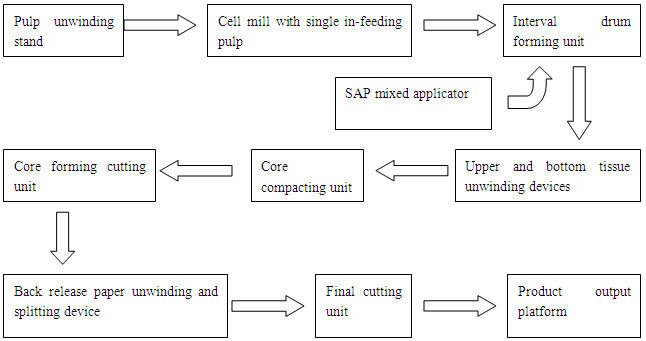

Main Compositions of Full-Servo Breast Pad Machine

-

1. Servo inverter drive

2. Pulp unwinding stand

3. Cell mill with single in-feeding pulp

4. Interval drum forming unit

5. SAP mixed applicator

6. Core compacting unit

7. Core forming cutting unit

8. Upper and bottom tissue unwinding devices

9. Top NW and laminated back sheet unwinding devices

10. Back release paper unwinding and splitting device

11. Final cutting unit

12. Reject gate

13. Bag type dust collection system

14. Product ordering output device

Main Technical Parameters of Full-servo Breast Pad Machine

|

Production Speed

|

600pcs/min

|

|

Required Power Supply

|

180Kw (air compressor excluded)

|

|

Power

|

380V, 50Hz, 3 Phases

|

|

Compressed Air

|

0.6-0.8Mpa, 1.2 m³/min

|

|

Ratio of Conformity:

|

≥80%

|

|

Dimension(for reference)

|

16m×5.5m×2.2m (L×W×H)

|

Flow Chart of Production Line

Shanghai Landytop Industry Co.,Ltd. is a professional manufacturer and supplier of nursing pad machines, specializing in the production of full-servo breast pad machines in China. In addition to these products, we also provide sanitary napkin machine,baby diaper machinery, adult diaper machine, under pad machinery, maternity napkin production line, etc. Our products have gained the CE authenticate and the standard attestation of ISO9001 International Quality System with their high quality. We follow strictly the standards for machinery industry formulated by the state. Our sales cover a wide range all over the world.