Description

Pulp core sanitary napkin machine mainly produces menstrual pads with pulp core. Menstrual pads are made from a range of materials, differing in style, country of origin, and brand. Different sanitary napkin production lines should be specially designed.Pulp core is made up of drum and wrapped by tissue paper (with SAP), N.W. fabric, PE film, back release paper, wing release paper, package film and easy tear tape. The absorbent core is made from fluff pulp. The addition of SAP sucks up the liquid quickly. There are several types of disposable menstrual pads.

Application of This Sanitary Pad Machine

Full-servo, semi-servo and inverter controlled pulp core sanitary napkin making machines are available in our company. Straight or winged sanitary pad machine can be made in this production line. We produce easy packing, individual packing and straight packing napkins. With different equipments, it can also be used to produce ultra-thin sanitary napkins. The most typical pulp core sanitary napkin machines are easy-open packing pulp core and ultra-thin wing sanitary napkin machines.

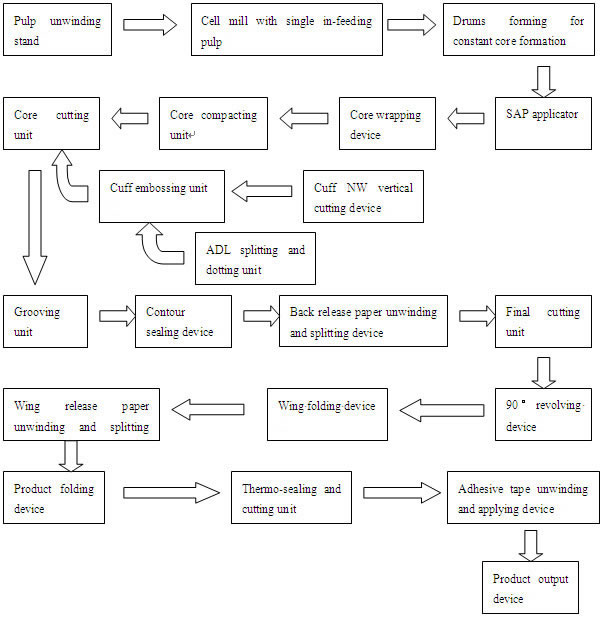

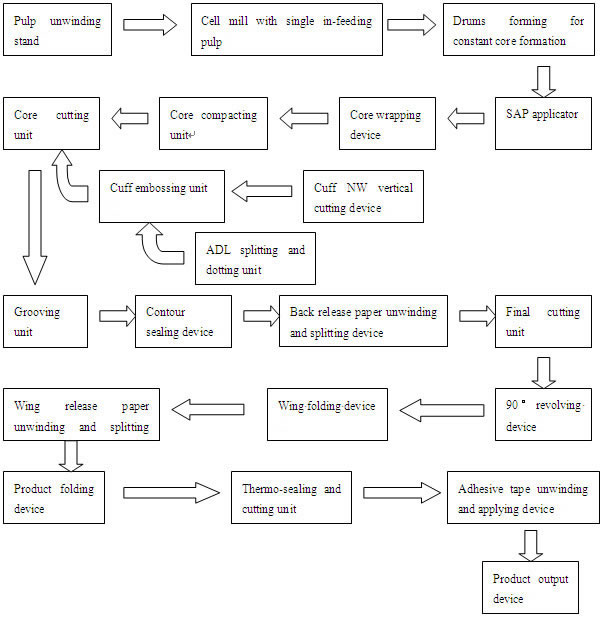

Typical Line: Easy-Open Packing Pulp Core/ Wing Sanitary Napkin Machine

-

Main Configurations of this Sanitary Pad Machine:

1. Inverter drive, PLC control with touch screen

2. Pulp unwinding stand

3. Cell mill with single in-feeding pulp

4. Constant drum forming unit

5. SAP applicator

6. Tissue /unwinding and wrapping device

7. Core compacting unit

8. Core cutting unit

9. Tension control raw material unwinding unit with auto splicing

10. 2 sides NW vertical cutting device

11. Side gather embossing unit

12. ADL cutting and dotting unit

13. Grooving unit

14. Contour sealing unit

15. Back release paper unwinding and splitting device

16. Final cutting unit

17. Wing folding device

18. Wing release paper unwinding and splitting device

19. 90°revolving device

20. Product folding device

21. Adhesive tape unwinding and applying device

22. Thermo-sealing and cutting unit

23. Reject gate

24. Product output device

25. Bag type dust collection system

Main Technical Parameters of This Pulp Core Sanitary Napkin Machine

-

Production Speed: 450pcs/min

Required Power Supply: 110Kw (glue applicator and air compressor excluded)

Power: 380V, 50Hz, 3 Phases

Compressed Air: 0.6-0.8Mpa, 1.2m³/min

Total Weight: 28 T

Dimensions: (m) L×W×H: 23×6.5×3.5 (for reference)

Flow Chart of Easy-Open Packing Pulp Core/ Wing Sanitary Napkin Machine

Shanghai Landytop Industry Co.,Ltd. is a professional manufacturer and supplier of sanitary pad machine, specializing in the production of pulp core sanitary napkin machines in China. In addition to these products, we also provide maternity napkin production line, hemostasia pad machinery, breast pad machine, pet diaper machine, pet pad machine and packing machine, etc. Our products have gained the CE authenticate and the standard attestation of ISO9001 International Quality System with their high quality. We follow strictly the standards for machinery industry formulated by the state. Our sales cover a wide range all over the world.