Maternity napkin production line mainly produces disposable products adopted by hospitals or families, especially when women excrete lochia in the early days of post-natal period. Maternity napkin machine is always used by middle or high class family for women after giving birth. We are original equipment manufacturer. We use plywood pallets with plastic film for packaging and container for delivery. For payment, you can choose T/T or L/C.

Features

1. Bearing, electric components and synchronous belt are import brands.

2. There is an anti-leaking PE bottom film in the of maternity napkin production line.

3. Main motor inverter control and mechanical transmission with differential gear boxes, universal shafts &timing belt.

4. The machine wallboard is processed by the large gantry milling machine.

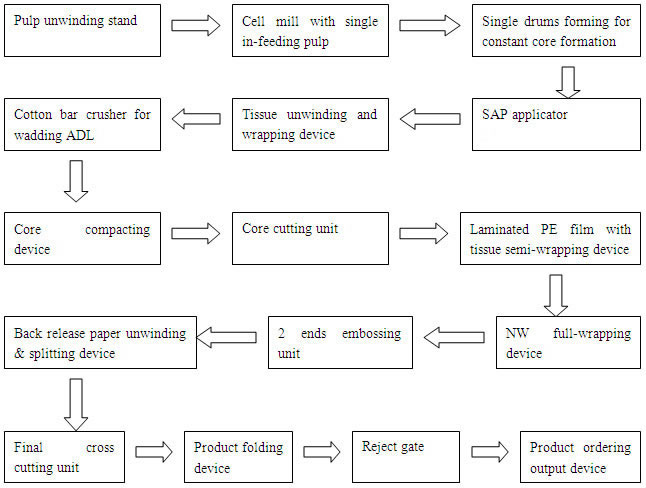

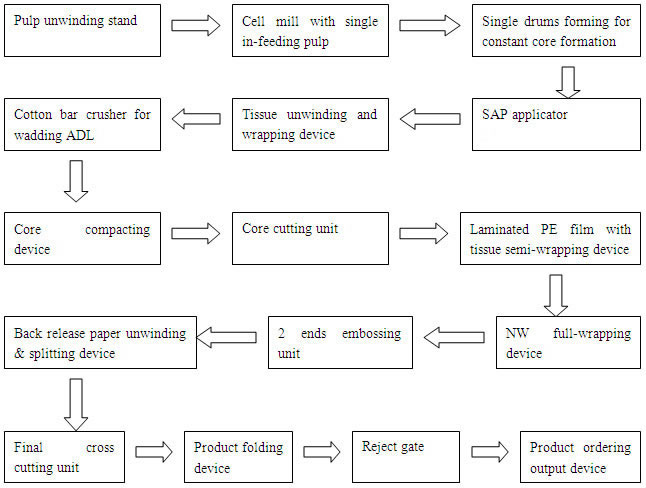

Main Configurations of Maternity Napkin Production Line

-

1. Inverter drive, PLC control with touch screen

2. Pulp unwinding stand

3. Cell mill with single in-feeding pulp

4. Single drums forming for constant core formation

5. SAP applicator

6. Tissue unwinding & wrapping device

7. Cotton bar crusher for wadding ADL

8. Core compacting device

9. Core cutting unit

10. Laminated PE film with tissue semi-wrapping device

11.NW full-wrapping device

12.2 ends embossing unit

13.Back release paper unwinding & splitting device

14.Final cross cutting unit

15.Product folding device

16.Reject gate

17.Product ordering output device

18.Bag type dust collection system

Main Technical Parameters of Maternity Napkin Machine

|

Production Speed

|

300pcs/min

|

|

Required Power Supply

|

100Kw (glue applicator and air compressor excluded)

|

|

Power

|

380V, 50Hz, 3 Phases

|

|

Compressed Air

|

0.6-0.8Mpa, 1.2 m³/min

|

|

Total Weight

|

About 23 T

|

|

Dimension (for reference)

|

17m×4.5m×2.5m (L×W×H)

|

|

Cycle and Delivery Time

|

within 5-6 months according to different product structures

|

Flow Chart of Production Line