Pet diaper machine mainly produces disposable products specially used by pets. Our company is a professional pet diaper production line manufacturer. We produce various kinds of diapers, including baby diapers, adult diapers and pet diapers. We also provide plywood pallets wrapped by PE film for packaging as per customer's requirement. According to specific product structure, we usually deliver products within 6 months. For payment, you can choose T/T or L/C.

Main Functions and Features of Pet Diaper Machine

1. This diaper machine can produce pet diapers with different lengths.

2. The machine uses advanced PLC and touch screen, which makes operation more simple and convenient.

3. The fluff adopts forming drum or aggregate pulp supply unit. It can produce three types of puppy diapers (L, M, S) with a few parts changed.

4. The pet diaper production line has non-woven top sheet, back sheet, film, waistband, frontal tape and side tape feeding devices.

5. The pet diaper machine adheres to form elastic ribbon for side leakage proof.

6. Main raw materials use tension control system.

7. After the side arcs are shaped, the wings will be three-folded lengthwise. The diaper will be output in line.

8. The machine wallboard is processed by the large gantry milling machine.

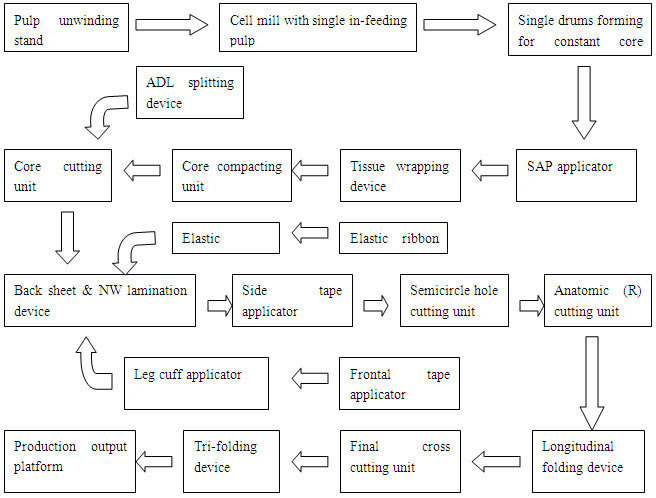

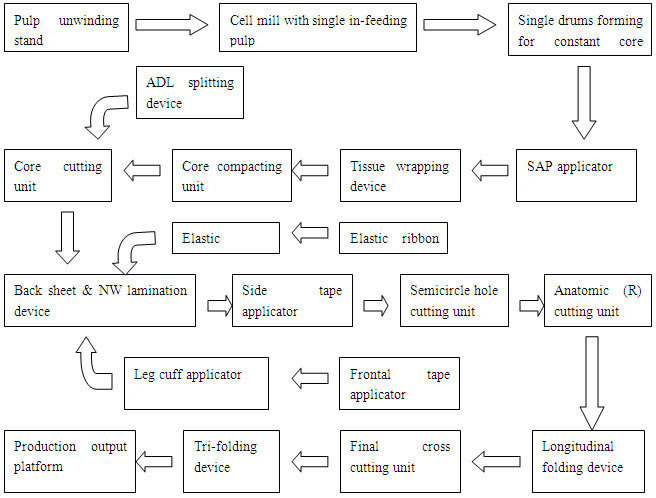

Main Configurations of Pet Diaper Machine

-

1. Inverter drive, PLC control with touch screen

2. Raw materials tension control and auto splicing

3. Quality control system with reject for defective products

4. Pulp unwinding stand

5. Cell mill with single in-feeding pulp

6. Single drums forming for constant core formation

7. SAP applicator

8. Tissue wrapping device

9. Core compacting unit

10. Tail hole of the core cutting unit

11. Core cutting unit

12. ADL splitting device

13. Elastic ribbon unwinding unit

14. Back sheet & NW lamination device

15. Elastic waistband applicator

16. Frontal tape applicator

17.Side tape applicator

18.Leg cuff applicator

19.Semicircle hole cutting unit

20.Anatomic (R) cutting unit

21.Longitudinal folding device

22.Final cross cutting unit

23.Tri-folding device

24.Reject gate

25.Bag type dust collection system

26.Safety door

Main Technical Parameters of Pet Diaper Machine

-

Production Speed: 350pcs/min

Max. Production Speed: 450pcs/min

Required Power Supply: 195 K w (glue applicator & air compressor excluded)

Power: 380V, 50 Hz, 3 Phases

Compressed Air: 0.6-0.8 M pa, 2.5m³/min

Total Weight: 42 T

Dimensions: (m) L × W × H: 26 × 7.5 × 3.5 (for reference)

Flow Chart of Pet Diaper Production Line