Description

A panty liner (also called pantiliner or panty shield) is an absorbent piece of material for female use. According to the direction of products in production line, we can divide panty liner machine into panty liner making machine with machine direction and cross direction panty liner production line. Machine direction panty liner machine can be used to produce pulp core or ultra-thin core panty liners. We can choose different equipments to constitute easy-open, individual packing and straight panty liner making machine. We can also select different drives according to different requirements. If the products need to be output arranged by groups, this machine can choose grouping device to reach the goal. The most typical product is easy-open packing panty liner machine(machine direction),which produces pantiliner products often used before or after menstruation or daily use. We use plywood pallets with plastic film for packaging and container for delivery.

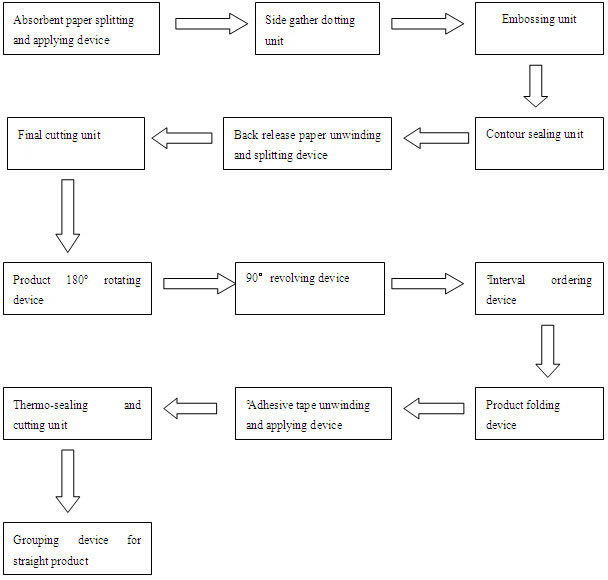

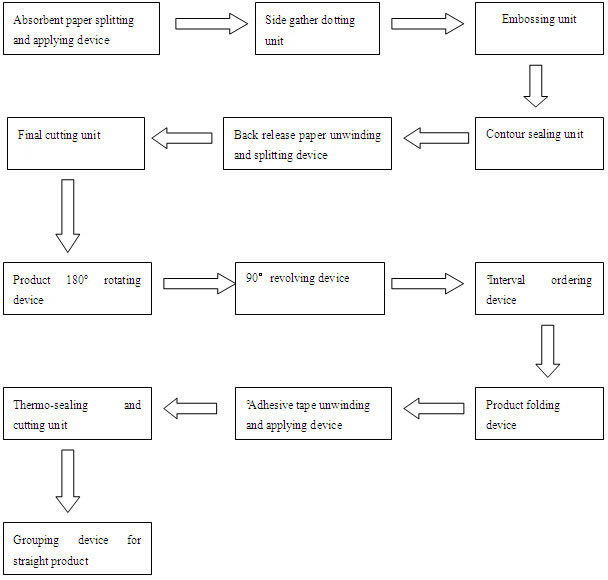

Typical Line: Easy-Open Packing Panty Liner Machine(Machine Direction)

Properties of this Panty Liner Making Machine with Machine Direction

a. The machine uses inverter drive.

b. Raw material unwinding is controlled by auto-controlling system.

c. The panty liner machine owns PLC controlling equipped with touch screen.

d. Man-machine conversation interface is designed in the operating terminal to realize figure digitalized control.

e. We have correction device and a high degree of automation.

f. Parts use CNC with high processing precision.

g. The machine has the function of automatic re-feeding the main material.

h. The machine wallboard is processed by the large gantry milling machine.

Main Configurations of this Machine Direction Panty Liner Machine

-

1. Inverter drive, PLC control with touch screen

2. Tension control raw material unwinding unit with auto splicing

3. Absorbent paper splitting and applying device

4. Side gather dotting unit

5. Embossing unit

6. Contour sealing unit

7. Back release paper unwinding and splitting device

8. Final cutting unit

9. Product 180º rotating device

10. 90°revolving device

11. Interval ordering device

12. Product folding device

13. Adhesive tape unwinding and applying device

14. Thermo-sealing and cutting unit

15. Quality control system

16. Reject gate

17. Bag type dust collection system

18. Grouping device for straight product

Main Technical Parameters of Easy-Open Packing Panty Liner Making Machine with Machine Direction

-

Production Speed: 600pcs/min

Designed Speed: 700pcs/min

Required Power Supply: 45 Kw (glue applicator and air compressor excluded)

Power: 380V, 50Hz, 3 Phases

Compressed Air: 0.6-0.8Mpa, 1.2m³/min

Total Weight: 18 T

Dimensions: (M) L×W×H: 16m×4.5m×2m (for reference)

Flow Chart of the Machine Direction Panty Liner Machine